Mechanical Testing

Prooftest Consulting Inc. is comprehensively equipped with state of the art equipment and dedicated machine shop to ensure rapid processing of customer orders.

Schedule Consultation

Tensile Testing

Tensile test is one of the most widely conducted test in mechanical testing of materials. Measurements obtained during test will provide data to evaluate material behavior under tensile load.

Ultimate Tensile Strength, Yield Strength, True Stress and Strain, Engineering Stress and Strain, the Elastic Modulus, the Fracture Stress, and Elongation, may all be determined by tensile testing.

Impact Testing

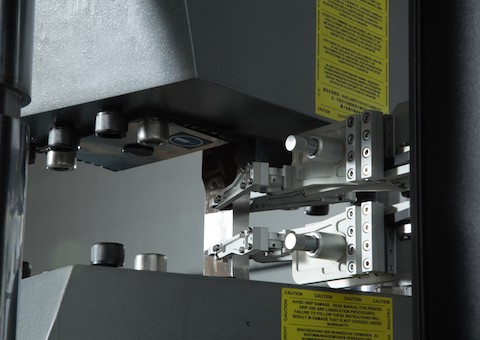

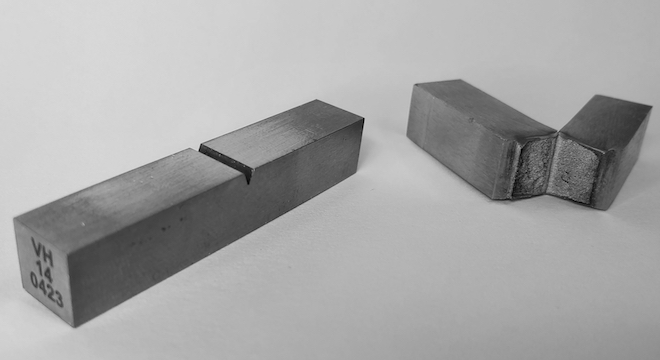

The Charpy impact test, also known as the Charpy V-notch test, measures a material’s toughness, ability to absorb energy and resistance to brittle fracture.

Prooftest conducts charpy impact testing on various types of steel products from raw material, welded joint to a complete finish product. Our laboratory is equipped with a charpy machine with a capacity of up to 450 Joules and capable of conducting tests at various temperatures from -196°C to ambient temperature.

Hardness Testing

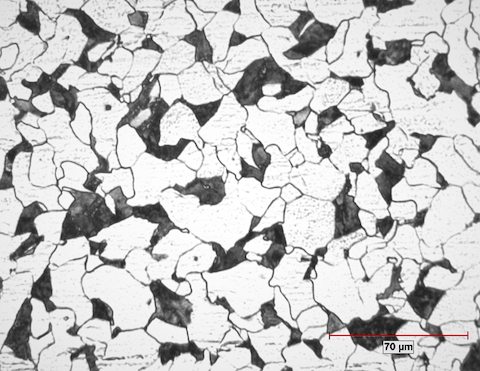

A widely used method for measuring the mechanical resistance of surfaces is hardness testing. There are various methods for testing the hardness of a component or material.

At Prooftest we provide Vickers and Rockwell hardness tests.

The Vickers hardness test uses a square-base diamond pyramid as the indenter. The included angle between opposite faces of the pyramid is 136°. This angle was chosen because it approximates the most desirable ratio of indentation diameter to ball diameter in the Brinell hardness test.

The Vickers test can be used for all metals since it has one of the widest scale among all hardness test methods.

The Rockwell Hardness Test is one of the most cost-effective hardness test techniques.

Rockwell hardness testing is an indentation testing method. The indenter is either a conical diamond or a hard steel ball. Different indenter ball diameters from 1/16 to 1/2 in. are used, depending on the test scale.

Compression Testing

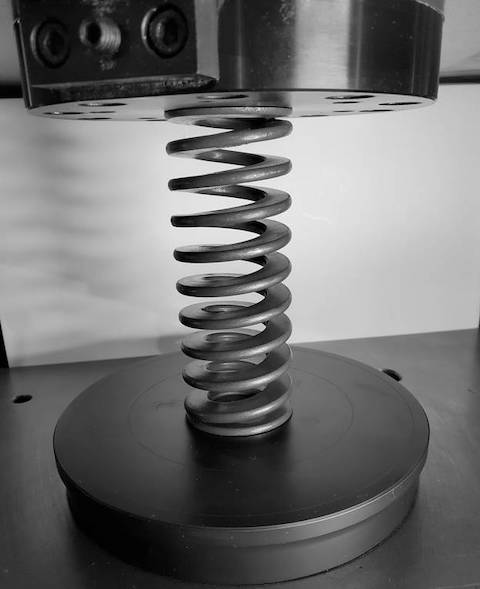

Compression testing besides tensile testing is one of the most essential types of mechanical testing.

Compression tests are used to determine a material’s behavior under applied compressive load. Compression testing permits companies to assess the integrity and safety of materials, components, and products during several phases of the manufacturing process.Prooftest can provide compression testing up to 600kN

Bend & Flattening Tests

Test method in which a specimen is bent to a specified bend radius by means of a jig. The bend test determines the quality of the weld at the face and root of a welded joint, as well as the degree of penetration and fusion to the base metal.

Various types of bend tests are used to evaluate the ductility and soundness of welded joints. The guided bend test is regularly used in welding procedure and welder performance qualification tests.